Optimal Timing for Polished Concrete Installations

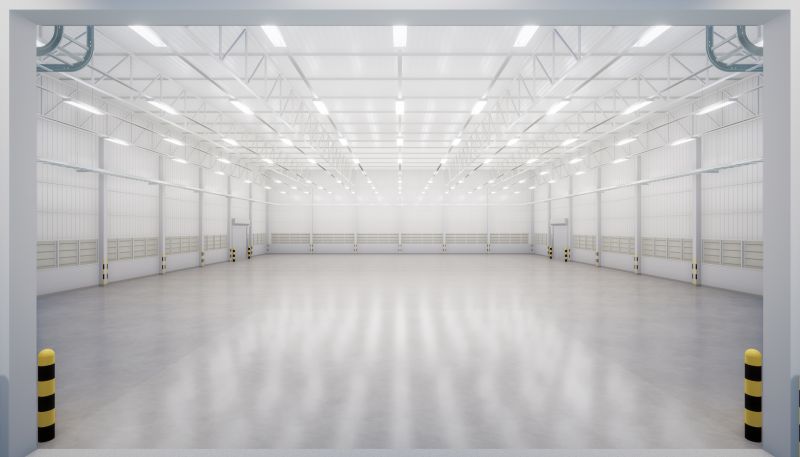

Polished concrete installations are influenced by various environmental and operational factors. The optimal timing depends on climate conditions, project scope, and facility usage. Proper scheduling ensures a high-quality finish and minimizes potential issues such as moisture problems or surface imperfections.

Spring and fall are typically preferred for polished concrete projects due to moderate temperatures and humidity levels, which facilitate proper curing and drying.

Extreme heat or cold can affect curing times and surface quality. High humidity may also impact the finishing process, making weather conditions a critical factor.

Scheduling during periods of low operational activity can reduce disruptions and allow for uninterrupted work and curing.

Avoid installation during rainy or very humid periods to prevent moisture-related issues and ensure optimal surface adhesion.

Ways to make Polished Concrete Installations work in tight or awkward layouts.

Popular materials for Polished Concrete Installations and why they hold up over time.

Simple add-ons that improve Polished Concrete Installations without blowing the budget.

High-end options that actually feel worth it for Polished Concrete Installations.

Finishes and colors that play nicely with Polished Concrete Installations.

Little measurements that prevent headaches on Polished Concrete Installations day.

Polished concrete is a durable, low-maintenance flooring option widely used in commercial, industrial, and residential settings. The process involves grinding and polishing concrete surfaces to achieve a smooth, glossy finish that enhances aesthetic appeal and longevity. Advances in polishing technology have made it possible to create high-quality finishes with minimal surface preparation, reducing installation time and costs.

Statistics indicate that polished concrete can extend the lifespan of flooring by resisting wear, stains, and chemical damage. Its reflective surface can also improve lighting efficiency within a space, reducing energy consumption. Proper timing of installation ensures the surface cures correctly, maintains structural integrity, and achieves the desired visual effect.

A 60-second routine that keeps Polished Concrete Installations looking new.

A frequent mistake in Polished Concrete Installations and how to dodge it.

Small tweaks to make Polished Concrete Installations safer and easier to use.

Lower-waste or water-saving choices for Polished Concrete Installations.

| Season/Time Frame | Key Considerations |

|---|---|

| Spring | Moderate temperatures, ideal for curing and finishing |

| Summer | High temperatures require early morning or late evening work |

| Fall | Cooler weather, suitable for installation before winter |

| Winter | Cold and moisture can delay curing, less ideal unless climate-controlled |

| Off-peak periods | Lower operational disruption, flexible scheduling |

Interested in scheduling a polished concrete installation? Filling out the contact form can provide tailored guidance and help determine the best timing based on specific project requirements and local climate conditions.